The need to protect your head, especially in combat, is by no means a novel one. The moment some ancient cavemen picked up a club the other cavemen realized the need to cover their head with something that will stop that club. Modern military helmets are just an extension of that tradition.

Regretfully, it is much harder stopping a bullet than it is to stop a wooden club, meaning that we need to use new technology and materials to stop the rounds.

Generally, there are three requirements for a good modern military helmet, regardless of the design:

- Ballistic protection against small arms and explosive fragments

- Lightness and comfort

- Compatibility with communication and other systems

History of Ballistic Helmets

While probably much older, the first combat helmets found by archeologists were from the Middle East and worn by ancient Sumerians. These were made of bronze and probably had a linen padding on the inside. Strangely enough, ballistic helmets are much younger even than firearms. While the renaissance already had quite advanced muskets, the lack of good materials to stop the round meant most armies used non-ballistic helmets as their usual gear. Additionally, because headshots with any type of firearm are relatively rare for multiple reasons, the needs weren’t as critical as it is today. Only with the First World War, the armies realized that artillery fragmentation and flying debris created a number of head injuries that needed to be protected from. This is when the first metal near-ballistic helmets gave rise across the world. An example of early ballistic helmets is the Adrian helmet used by French troops, which was made from mild steel. Later, with the development of ballistic materials like Kevlar or Twaron the modern military helmet was created. These models can not only stop any type of explosive fragmentation but are also capable of stopping some of the rounds a soldier might be at risk from on the battlefield.Ballistic vs. Tactical Helmet

While they may be visually similar, and technically all ballistic helmets are also tactical, not all tactical helmets have ballistic capabilities. There are types of military headgear that are useful in the field but offer no protection from either gunfire or explosives. One of the most common types of these helmets is the so-called ‘’bump helmet’’ which is primarily made from advanced plastics. These items are made to be extremely light and offer protection from cold weapons and debris, as well as any type of blunt force trauma. But, unlike ballistic helmets, bump helmets won’t stop any type of bullet and most of the explosive frag will cut right through it. This makes them inadequate for the battlefield and more inclined to rescue missions, extractions, or training.Parts of the Military Helmet

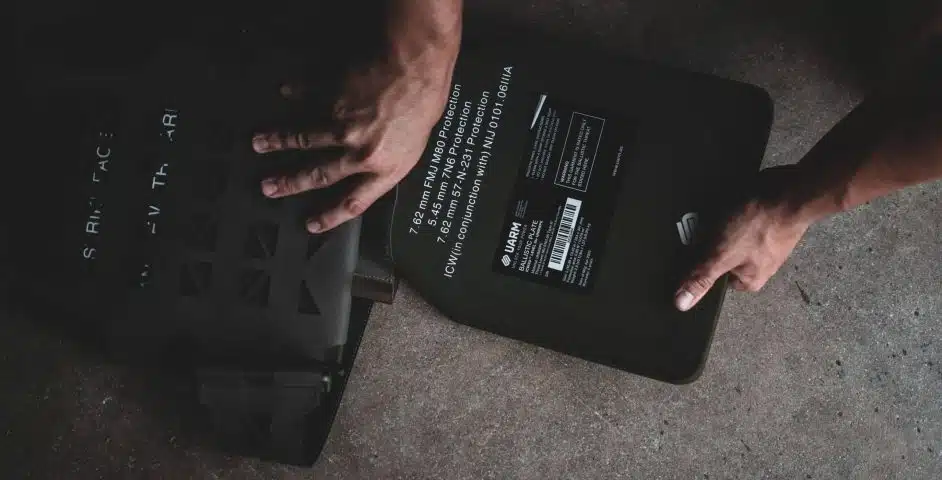

Modern military helmets are rather complex and need to be made from a number of materials depending on the part. Regardless of the type of modern materials used, most military helmets will have a similar design. This is because the idea behind it is to reflect the impact and the projectile away from the operator. A direct hit to the head is not only dangerous if penetration happens, but also can be detrimental due to the sheer kinetic force impacting the head and the neck. For such an occurrence, the helmet needs to absorb most of the impact and transfer it somewhere else if possible without affecting the wearer. Additionally, any type of communication device, cameras, ocular assistance, or similar gear needs to be balanced on the head. Making the wearer disbalanced this high on the body can reduce maneuverability significantly even if the helmet itself is not as heavy.Shell

This can be considered the main part of the helmet. The shell is the part that is meant to take the hit and should be made from layers of ballistic materials capable of stopping the round and diverting as much of the force as possible. Modern helmets will usually be made from a top layer of hardened plastics that will stop the inner ballistic fibers from wearing and tearing or being damaged by the elements. This will also stop any blunt trauma from even being noticed by the operator. The inner part of the shell is made from one or more layers of ballistic fiber material, usually being some variation of aramid fabrics impregnated with resin. While originally materials like Kevlar were used, the most recent helmets use Twaron. Ideally, the composites will be streamlined around the head to force any backface deformation (BFD) to the back of the helmet and away from the head. Otherwise, a simple grazing hit might cause a concussion and disable the operator.Padding

Under the hard shell of the military helmet, you will always want to have some padding. This material offers no ballistic protection on its own but can improve both the protection of the shell and the comfort of the operator. Primarily, it is used to absorb any kinetic force attaching the helmet and use inertia to protect the wearer from harm. But, aside from the hit, the padding should also be able to absorb moisture from the head and make the soldier wearing the helmet comfortable under it. With new modular armor, the padding can also be moved and adjusted to fit any shape of the wearer’s head.Fastening

To keep the helmet securely on the head even when running, climbing, or jumping, every modern military helmet will need to have strong and adaptive fastening. This will usually be done by connecting multiple points of the shell with the chin of the operator. Any fastening used should be both flexible and impervious to tears. For such a reason, the best modern helmets use materials such as Cordura that have all of the necessary properties needed. The straps need to be thin and light as not to decrease the inner volume of the helmet but also need to withstand constant pulling of several-pounds heavy helmets and the nips and tears that often happen between the gear.Covering

It is not essential for a helmet to have a covering. Many of the battlefield helmets, especially those made with a low cut, don’t have the option to install a covering at all. But, those who want to increase the tactical ability of the helmet can often do it this way. Overall, there are three types of coverings:- Ballistic

- Adhesive

- Camouflage