Although the collective terms for body armor doesn’t actually specify what is body armor made of when talking about ballistic protection we have some tried and tested materials. For those of us who haven’t been to the proper schools to know the exact processes of how these fibers and ceramics work, we need to observe how they act and what their purpose is.

There are two distinct categories of body armor, soft and hard, and each have been made with different materials, most of which are obsolete by now:

- Modern Soft Body Armor

- Aramid

- Silicon Carbide Particles

- UHMWPE Fibers

- Modern Hard Plate Armor

- UHMWPE

- Boron Carbide (B4C)

- Silicon Carbide (SiC)

- Aluminum Oxide (Al₂O₃)

Also, there are non-ballistic materials used to keep the heavier elements in place, as well as to make the body armor more comfortable. Depending on the design and intended use, these materials will also differ.

Finally, new materials are being explored and tested every day. Most of the current solutions weren’t even considered possible just a couple of decades ago, and are now staple choices for the highest quality body armor.

Soft Body Armor, Hard Body Armor, and Auxiliary Armor

The biggest differences are between soft and hard armor. Soft armor, that is meant to protect from handgun ammunition is made from flexible fibers that catch the bullet and dissipate the force, protecting your body.

While an average user might opt to wear either one or the other, difficult combat situations will usually require a combination of both. Hard plates will be used on the torso, while your head, neck, stomach, groin, and libs will be protected with soft body armor options.

Hard armor panels are heavier and denser and are meant to stop the round in its place and transfer the impact force to a much larger area. Hard plates are much more difficult to carry around and you won’t be able to withstand the plate carrier for more than a couple of hours. But, they are the only thing that can stop a rifle round, especially when it comes to armor-piercing.

Weight and volume are important for both types of armor, and the reason why new materials are introduced is that they are easier to carry. Old soft armor way made with layers upon layers of folded cloth. But, the thickness of that cloth made the wearer less agile, which is something you want to avoid.

Finally, there are non-ballistic elements that bind all of that gear together and make it more comfortable to wear. The quality of these is often disregarded, even though the comfort of the user adds a lot to their overall performance.

Soft Body Armor Materials

Modern soft body armor is fairly amazing if you think about it. Materials like aramid and polyethylene can be really thin and still protect from serious ballistic impact. The high tensile strength and low weight make them ideal choices when it comes to body armor.

You will notice that most advanced materials are proprietary brands and they all have their little advantages compared to competitors. While differences in protection will be negligible on a practical scale, flexibility and weight will change, depending on the goals of the manufacturer.

Generally, soft body armor panels are between 4mm and 10mm thick, ranging from NIJ Level IIa to IIIa. This allows for some ingenious solutions, like covert armored clothing and comfortable ballistic shirts, which were impossible before the invention of these materials.

Aramid Fiber – Kevlar®/Nomex®

Aromatic polyamide, or Aramid, is the closest thing we have made to magic yet. It is very light and incredibly strong, as well as resistant to fire, water, and oxidation. Also, aramid is non-combustible and only melts under extremely high temperatures.

Chemically, unless you can either introduce enough energy to dissolve the amide bonds or rip through the O-H bonds, you aren’t getting through aramid.

DuPont was the first to introduce aramid commercially, under the name Nomex®. Once the ballistic resistance of the material was established, they improved the formula to make para-aramid, which is now sold under the household name of Kevlar®.

Silicon Carbide Particles – Twaron®

Twaron® also uses aramid as a base for their product. It is actually one of the most common types of aramid products around.

But, unlike with lone aramid sheets, there are silicon carbide particles impregnated into the fibers, making them more durable and resistant to ballistic impact.

This does increase both the thickness and the weight of the armor but adds a lot more to resistance.

Polyethylene – Dyneema®/Spectra®

Polyethylene is ten times as strong as steel and fifteen times more resistant to abrasions. When it comes to impact rating, it is even stronger than aramid. But, it has some differences that don’t always make it an ideal choice.

Depending on the number of fibers woven, as well as the way they are arranged, PE can range from abrasion-resistant protective surfaces to hard plate armor. They are the main material in UHMWPE Level III armor when they are laid down very thick.

Somewhere in the middle, it will still retain some of its flexibility and can be used as soft body armor with a high degree of versatility.

Hard Body Armor Materials

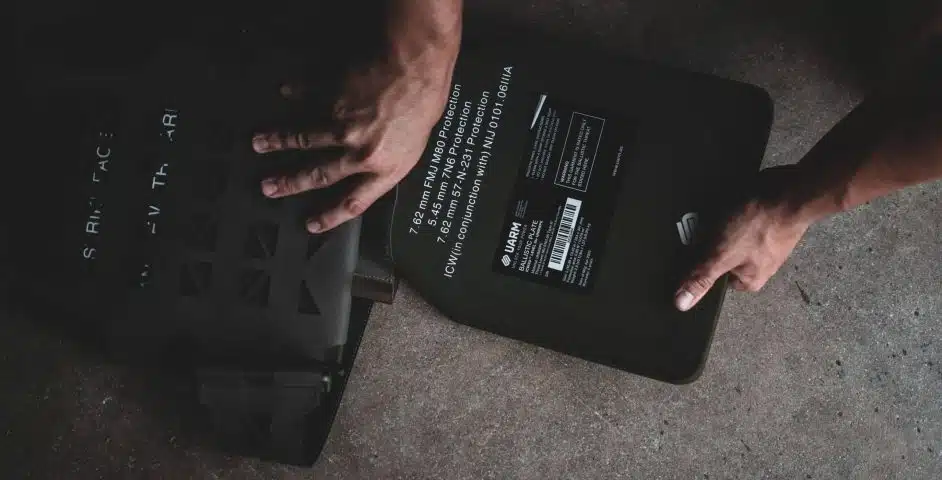

Hard body armor is made to protect your vital areas and reduce the risk of fatal injuries to your torso when under rifle fire. While they are relatively dense and heavy compared to their size, the relative ballistic protection they offer is unsurpassed.

UHMWPE

As previously mentioned, UHMWPE is very strong compared to its weight. Unlike some other options for hard armor, an AP round can still find its way through if you are unlucky, so it can’t be certified as NIJ Level IV armor.

But, the lightness it can provide makes it ideal for mobile troops that need to do a lot of running, as a plate with the carrier can weigh as low as 7lbs.

Boron Carbide

Boron Carbide is the third hardest material known to us, only falling behind cubic boron nitrate and diamonds. This makes the information that it was found by accident even more amazing, as boron oxide crystals were mixed with burning petroleum coke.

It is one of the best ballistic materials we can have, due to its small weight and extreme hardness, but it is also quite expensive to make. Also, it is more brittle than other materials, making the final hard plate endure fewer hits than some other options.

But, the hits it can endure would blow any other material into smithereens.

Silicon Carbide

Also known as carborundum, silicon carbide is a semiconductor and one of the hardest materials in the world. It is used to make some of the toughest NIJ Level IV armor plates and is even flexible enough to withstand multiple hits.

While science has known about SiC for over a century now, it was hard to make enough to make plates viable and was mostly used as an abrasive. Now, it is one of the most common choices when it comes to Level IV hard plate armor.

Aluminum Oxide

Often called ‘alumina’, this oxide is very cheap and very easy to make. Combine that with its incredible hardness and it becomes on the most popular options when it comes to body armor.

The reason why we can’t make these plates at home is that normally air would oxidize only the outermost layer of aluminum, and we need the whole thing. Thankfully, if you have a factory it is easy to make whole plates of alumina and make plates to stop bullets.

Non-Ballistics Materials Used in Armor

Most manufacturers of tactical gear will use the same proprietary materials when it comes to ballistic fibers and plates. But, the genius of the designers will be expressed in how they can pack them in non-ballistic materials.

Making your plate carrier comfortable, easy to put on and off, or even accessible to medics if there is a bullet wound will increase the defensive value of your body armor, and thus increase your overall combat ability.

The range of these options can be really vast, and it will be up to the wearer (or the quartermaster) to decide. Making a good combination of ballistic and non-ballistic parts of the armor will impact how it acts in the field, and we must be certain that our choice will be adjusted to the mission we must accomplish.